Videolift

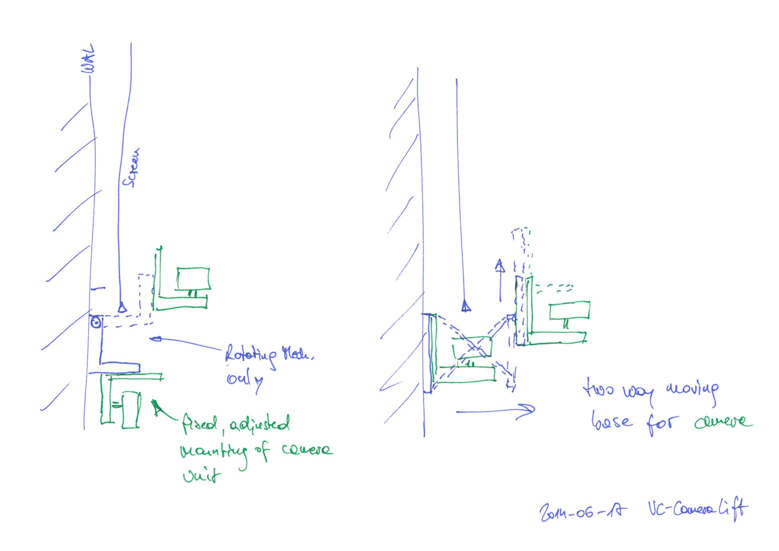

The whole project started out with sketches of the customer showing

the location and his thoughts about the problem and possible solutions.

As you can see, it was considered to use a lever-type mechanism or maybe a linear lift.

Soon it turned out, that tipping the video conference

system forward would cause the cameras to fall out of the

casing made by Cisco.

I didn't like linear rails either, because I think, that they would

extend forward more than necessary. The linear drives are pretty expensive,

and hard to synchronise left to right, unless one used a not very elegant open shaft.

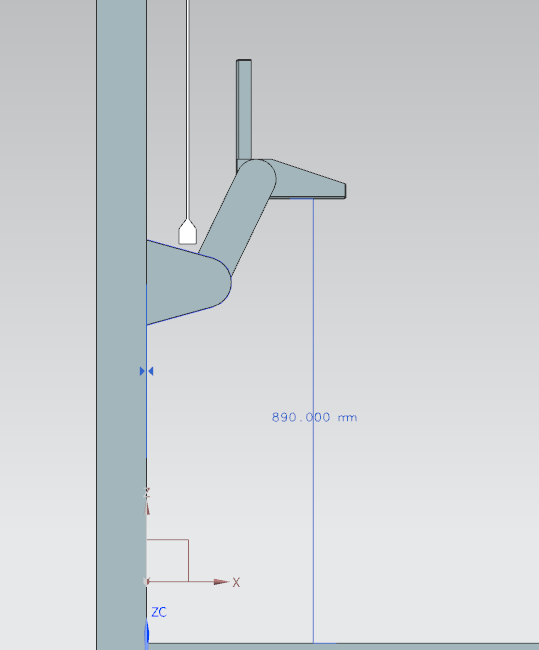

So I came up with a swinging arm construction with an internal mechanism,

to keep the camera system upright.

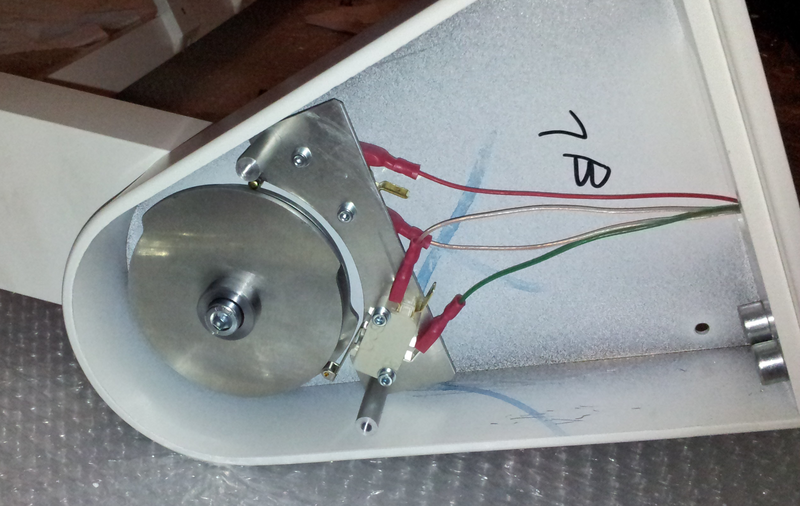

The customer and I agreed, that it would be favourable, if the drive

motor and gearbox could be placed into the drywall construction.

It took quite some time and effort to find a gear manufacturer,

that was able to provide a drive small enough, and capable of supporting

the belt forces. But finally we managed to squeeze the entire drive

unit into the 90mm spacing of the drywall.

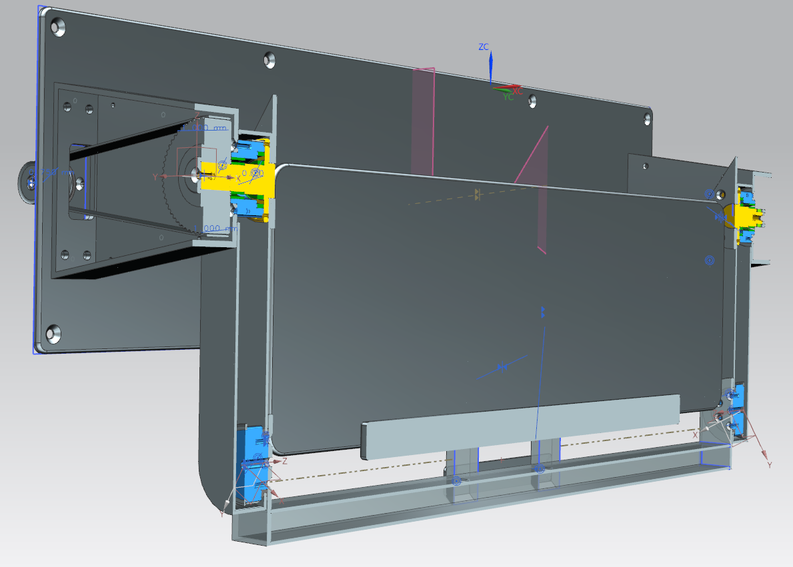

This is a CAD-model of the lift. A circular translation of the

video system is achieved by timing belts and sprockets of equal

diameter inside the arms.

The wall side sprockets are fixed to the wall frame and serve

as bearing housings as well.

The other two sprockets are fixed to the video-support frame.

Since the timing belt rolls off one sprocket the same as

it rolls onto the other, the sprockets are kept in angular synchronicity,

while the arms are swinging up and down, and thus the video-support frame

doesn't tilt.

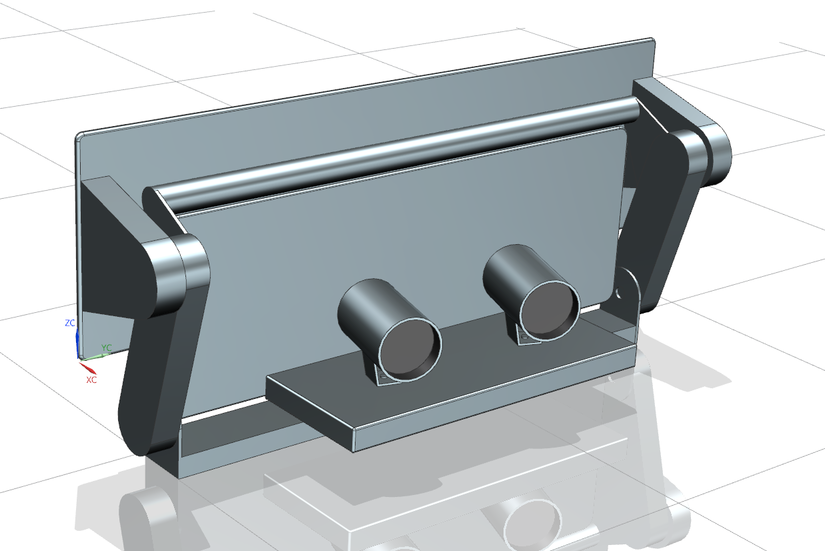

Below some of the parts after welding.

As you can see now, two systems were built.

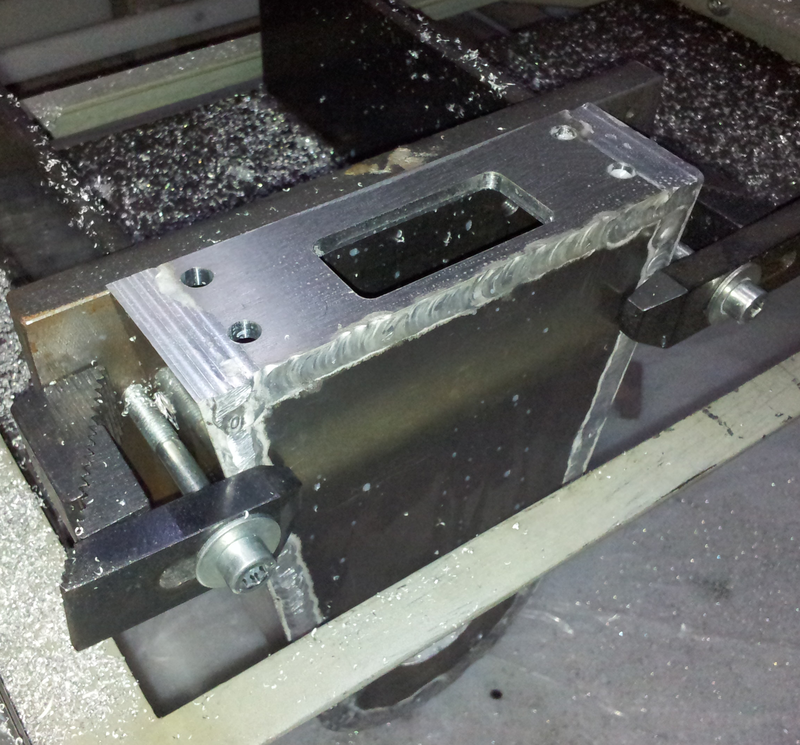

One of the consoles during CNC-milling.

The Mechanical assembly is almost finished.

In the background of the arm you see a sprocket-bearing-liftshaft assembly for the 2nd unit.

Cam-assembly of the end-stop switches.

Here the Project coordinater of my customer is doing final touches on the cabling,

after the unit has been mounted into the wall of his customer.

Ready to test!

The video system in operation - I'm the guy with the sanctimonious gloriole.